JK-A02 Computerized full automatic Polo front placket sewing machine

| Model | JK-A02 |

| Cutter | Install single blade or double blade |

| Cutting mode | Single blade in the center, cut big and small edgeDouble balde in the center, cut width is adjustable. |

| Power supply | Single phase 220v, 50/60Hz, 1.8kw |

| Air pressure | 0.5-0.6Mpa (5-6kgs/cm2) |

| Needle | DBX1 10#-12# |

| Sewing precision | 0.02mm more or less |

| Sewing needle pitch | 1-5mm |

| Sewing speed | 3600rpm |

| Sewing width | 60mm |

| Sewing length | 360mm |

| Sewing time | 3-8/piece (depends on the size of workpiece) |

| Production efficiency | 2000-2800pieces/10 hours |

| Dimension | 160x88x141cm |

| Weight | 260kgs |

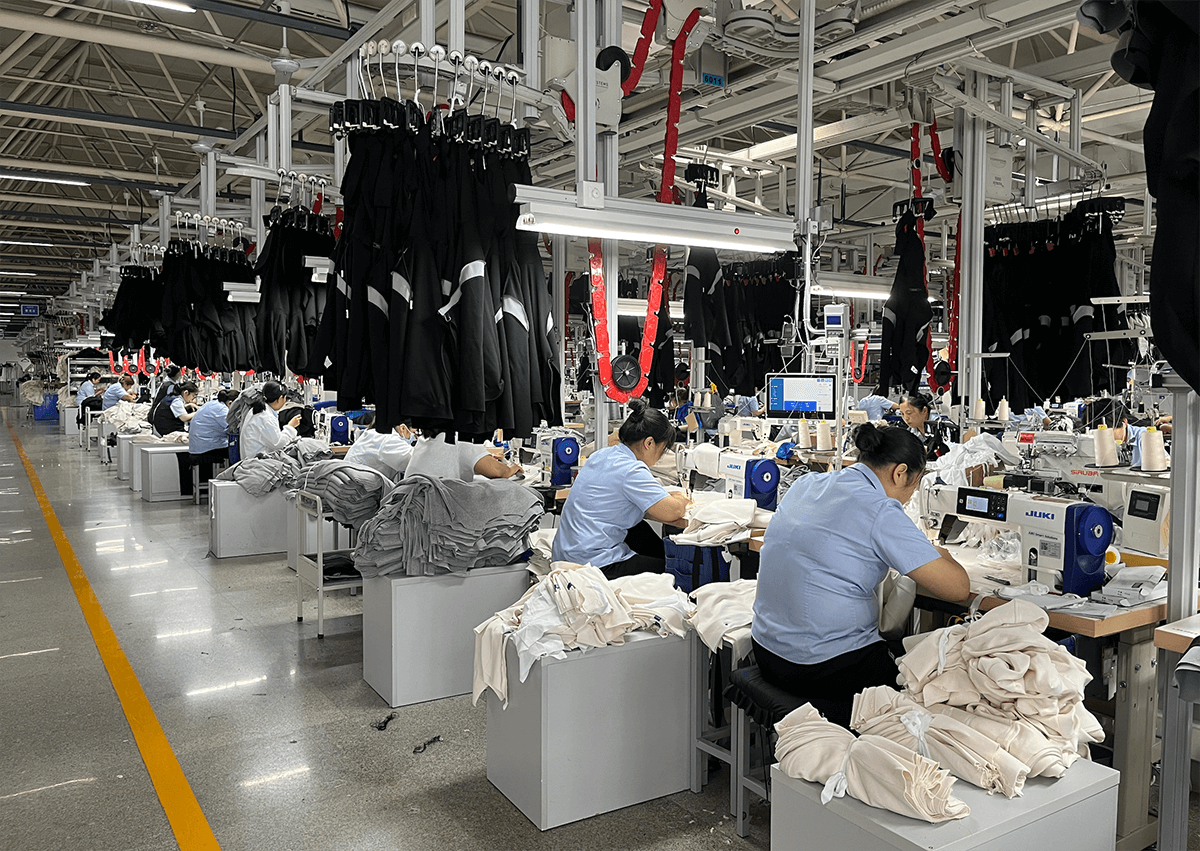

Ordinary clothing factory production sewing T-shirt unilateral placket, bilateral door . There are some problems of the laper, open word bag etc. various placket. T shirt placket hand hard sewing, tailoring from fabric measurement, Sewing and collecting multi-channel processes such as high-end T-shirt placket required more High.

T shirt placket sewing by hand easy to fold, rework, quality

Difficult to ensure that the production efficiency is low.

Therefore, stitched placket industry Art is not easy, need rely on skilled worker to do.

JOCKY computerized placket sewing machine JK-A02 is professional, intelligent, automation fully solve the clothing T-shirt single side placket, bilateral placket, open word bag placket sewing prone to wrinkles and problem of multi procedure. Not only improve the production efficiency, but also get rid of dependence on skilled workers. Ordinary people in 20 minutes to learn the simple operation, automatic completion of disposable sewing and tailoring.

Intelligent control, automatic wire cloth.

Apply famous brand elements.

Independent cutter device: Apply dual shaft structure, the cutter device is developed with independent intellect-ual property and world original patent technology, which assure stable movement and less wearing for cutter.

Intelligent touch screen: Micro computer control, intelligent touch screen display simple program, select English language click, there is 2 standard modes: single / bilateral placket solution.

Movable needle plate: Slotless and movement needle plate is the patented technology for assuring smooth fabric movement and keeping fabric flat during sewing.