JK-F161 Automatic elastic ribbon/tape splicing machine

Introducing the JK-F161 Automatic elastic ribbon/tape splicing machine, the perfect solution for efficient and precise splicing of elastic bands. This advanced machine combines two types of splicing - stacking and flat splicing, allowing for versatile applications.

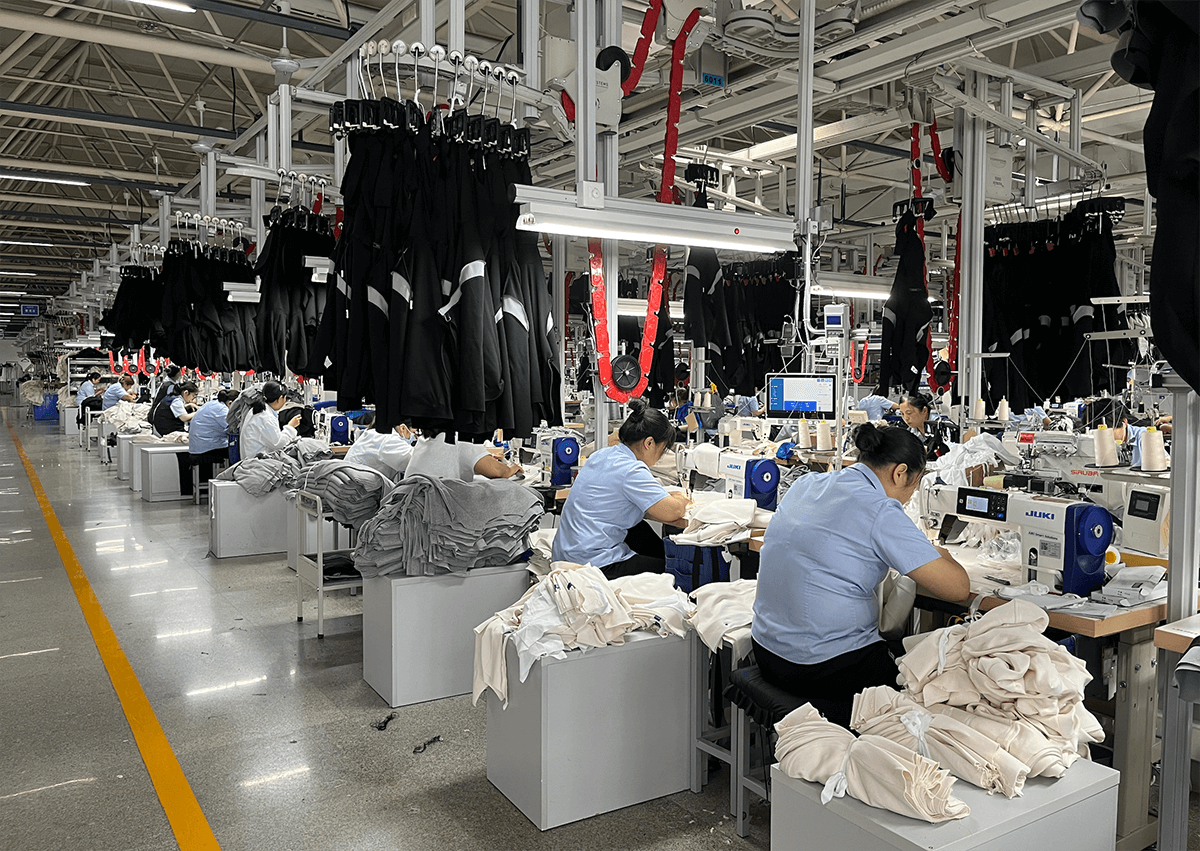

With its automatic operation, this machine streamlines the splicing process, encompassing feeding, cutting, splicing, and receiving all in one seamless operation. Thanks to its innovative design, one worker can effortlessly operate up to 5 sets of machines simultaneously, greatly increasing productivity and reducing labor costs.

One of the standout features of this machine is its easy adjustment of size. It is equipped with special locking nuts that are specifically designed to significantly reduce the difficulty of adjusting the size of the elastic bands. This ensures that the machine can effortlessly adapt to different sizes of bands, providing flexibility and convenience in production.

Another impressive feature is the machine's ability to automatically stop when there is a joint or when the elastic bands run out. This eliminates the need for constant monitoring, allowing workers to focus on other tasks without worrying about potential issues. This automated stop function not only improves efficiency but also avoids any potential damage or mishaps that may occur.

In addition, the JK-F161 incorporates the use of the Panasonic color-coded identification system for two-color rubber band sewing. This system accurately identifies the position of the logo, ensuring precise alignment between the logo and the elastic band. This guarantees a flawless and aesthetically pleasing outcome, enhancing the overall quality of the final product.

Overall, the JK-F161 Automatic elastic ribbon/tape splicing machine is a game-changer in the industry, offering a wide range of features that enhance efficiency and precision. Its automatic operation, easy size adjustment, automatic stop function, and precise logo alignment make it the ideal choice for any company seeking to streamline their elastic band production process. Trust in the JK-F161 to take your elastic band splicing to the next level.

| Model Number: | JK-F161 |

| Stitch Length: | 0.05-12.7 mm |

| Overall Dimensions: | 1220x1220x1440 mm |

| Sewing area device: | 100x70 mm |

| Weight: | 120/150 KG |

| Power: | 750W |

| Air pressure: | 0.5Mpa |

| Height of press foot: | 25mm |

| Place of Origin: | Zhejiang, China |

| Max. Sewing Speed: | 2700 rpm |