JK-N800 Needle Inspected Machine Needle Detector

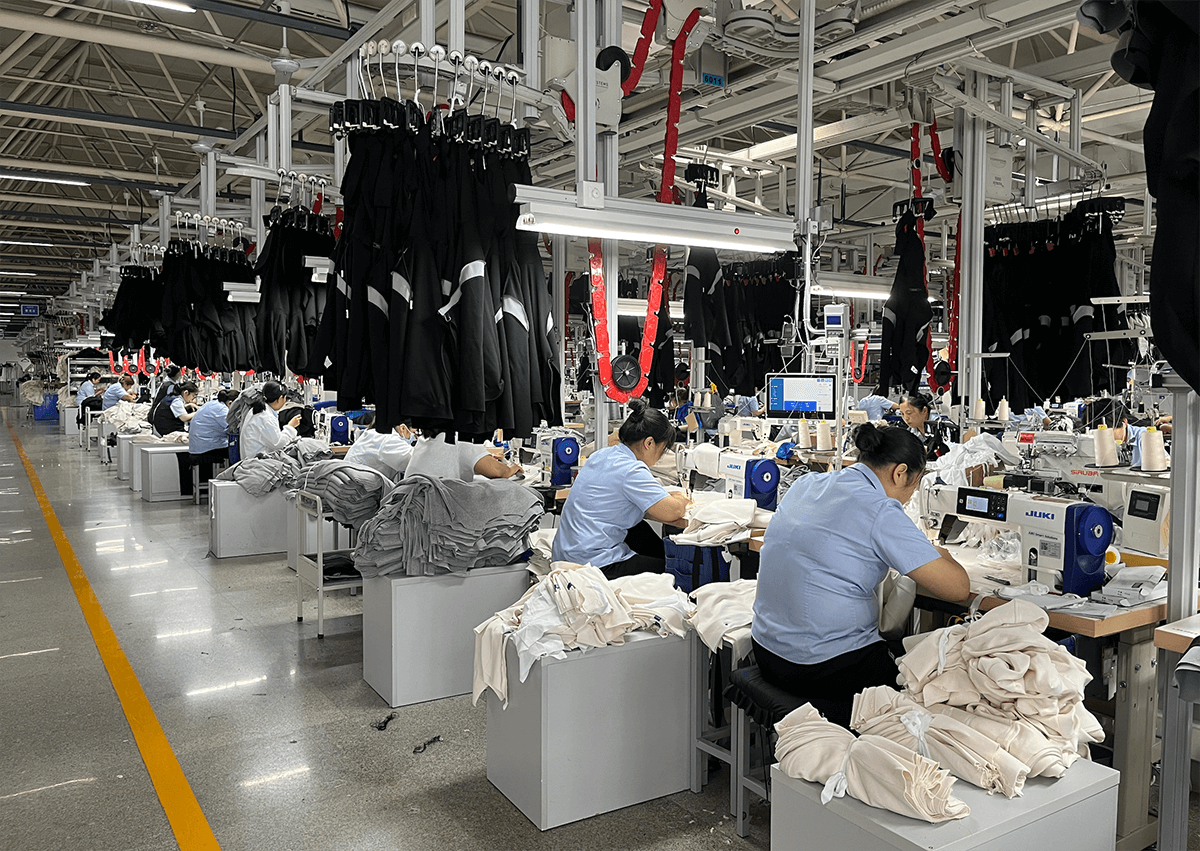

Application:

Automatic conveyor magnetic induction metal detector can use it to detect the needle or ferrous pieces of sewing products, (such as:male clothing,female clothing, child clothing, underwear, kimono, jacket, bedclothes, shoes, gloves,cat. toll, blanket and healthful ware.) And it can detect the cloths of slide fastener, button and use it to detect the ferrous which mixed in nonferrous material. Such as copper, aluminum, zinc, paper, rubber, chemicals…etc

When detect the accessory of sewing article.Such as:Slide fasteners, button, hook…etc. It needs non-magnet products(It may needs to damagnetized).

When operator is using machine, please take off the all accessory from the body. Cause machine will react to moving matals and will alarm mistake.

Feature:

Automatici conveyor magnetic induction metal detector can detect the needle easily.And it has signaler to tell you there is some ferrous in it.

When machine detects the needle or ferrous,the alarm will sound and the conveyor will stop.The signal light will show the position where the needle or ferrous are and will return the disqualified,which increase the efficiency of working.

Machine equips with counter and it can count the quantity of qualified.

It can adjust the sensitivity of detecting and to meet the different kind and size of detected objects in order to let you to find the needle or ferrous in your detecting products.

It adopt the newly design of trans-induction device.It increase the product of detection and reliance.

| Technical | |

| Suitable material | Cloth,Garment,Shoes,Textile Product Inspection |